It has been found that the most differentiating factor to survive earthquakes with least damage is the use of high-quality TMT bars which should stick to minimum requirements defined in IS 1786-2008.

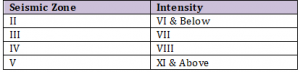

Based on scientific inputs for seismicity, earthquakes in the past and tectonic setup of the region, Bureau of Indian Standards (BIS) defined four seismic zones which mapping intensity levels of earthquakes:

Cities / towns in India majorly fall under Seismic Zones III, IV and V; and hence an increased focus on earthquake resistant construction in the country is need of the hour.

- Zone V: The areas under zone V are most vulnerable to earthquakes; Entire northeastern India, parts of Jammu and Kashmir, Himachal Pradesh, Uttaranchal, Rann of Kutch in Gujarat, part of North Bihar and Andaman & Nicobar Islands.

- Zone IV: Remaining parts of Jammu and Kashmir and Himachal Pradesh, National Capital Territory (NCT) of Delhi, Sikkim, Northern Parts of Uttar Pradesh, Bihar and West Bengal, parts of Gujarat and portions of Maharashtra near west coast and Rajasthan. Read more...